lot traceability system

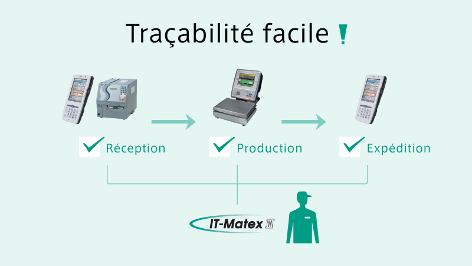

Lot traceability is an essential tool for any and all production processes and a dedicated manufacturing ERP software will ensure timely accurate and reliable inventory and production workflows and reporting. A warehouse management system WMS makes it much easier to gain traceability throughout your warehouse.

What Is Traceability Traceability Solutions Keyence America

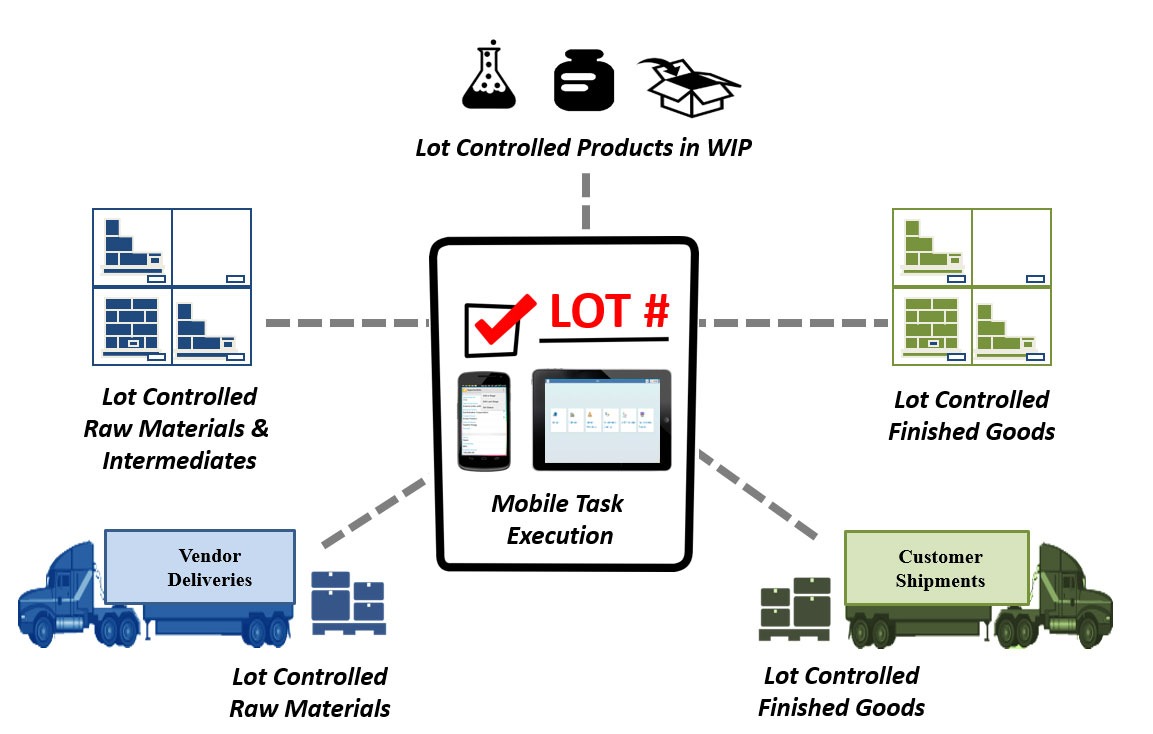

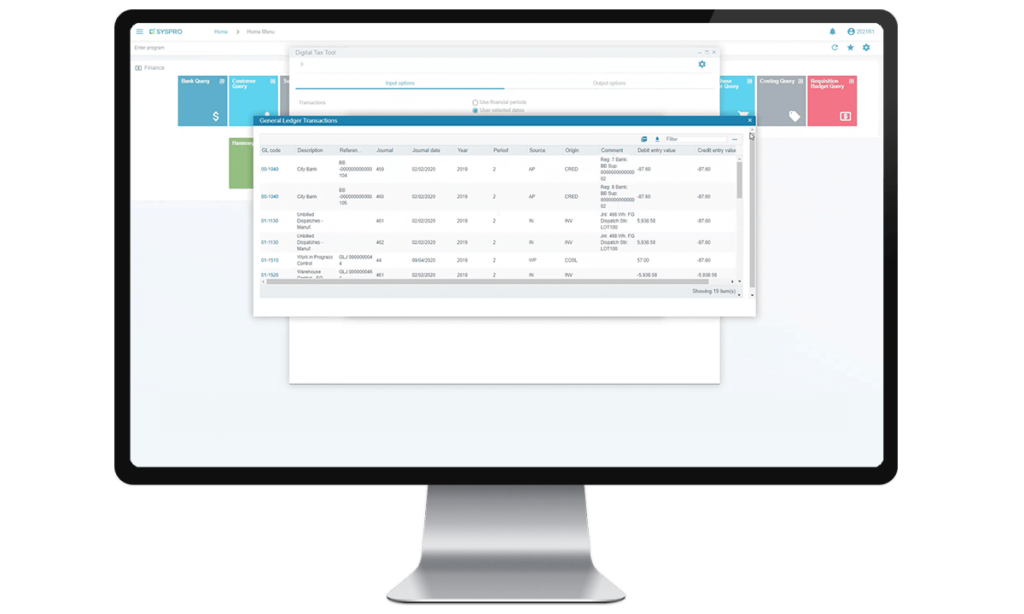

SYSPRO Lot Traceability ERP systemusers can track materials from vendor receipt through delivery of the product to the customeras well as all levels in between.

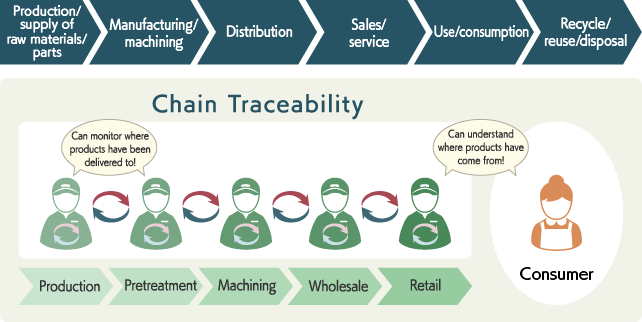

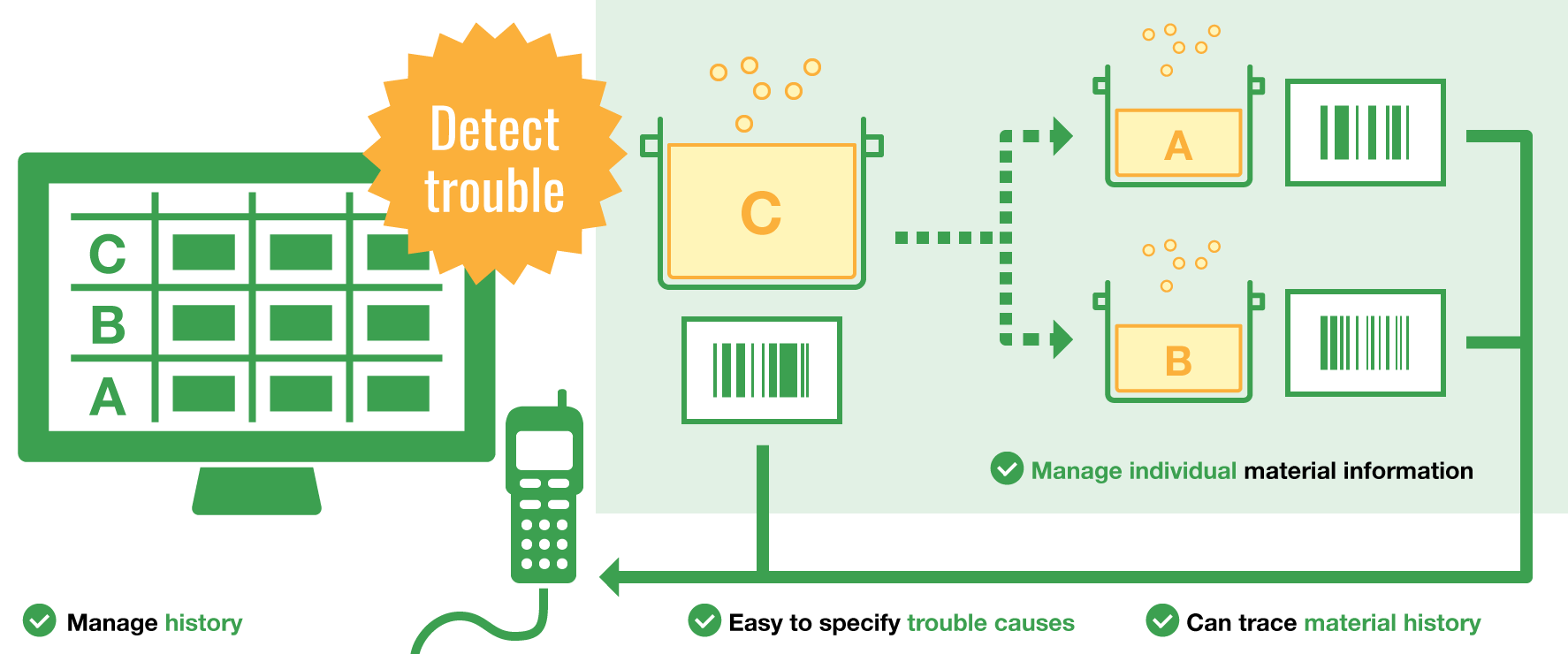

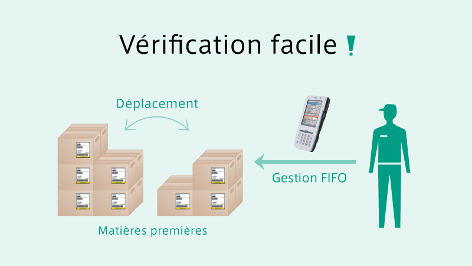

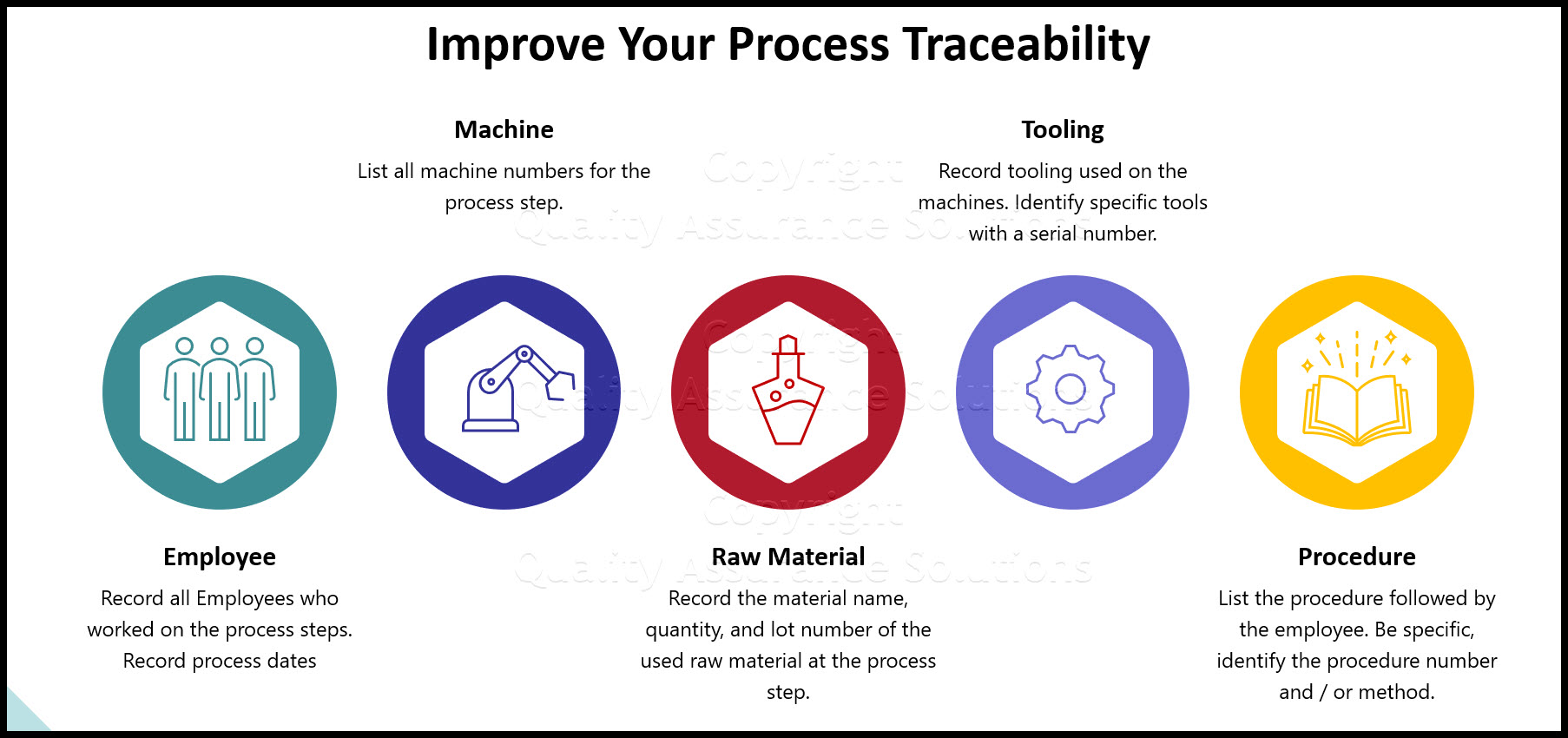

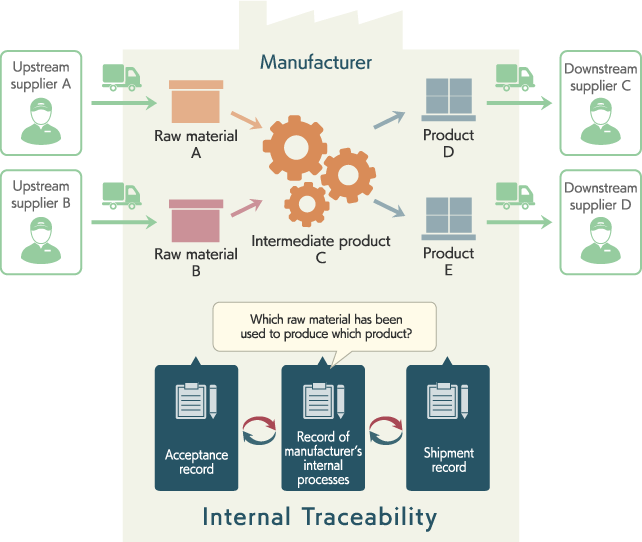

. Lot detection should be related to significant occurrences or features in the processing process for the purposes of traceability. Lot traceability also known as Lot control or manufacturing traceability means a system which has the comprehensive functionality to track problems and provide full visibility of the exact make-up of consumer goods in real-time throughout its manufacturing process. Lot traceability also called lot tracking lot control or manufacturing traceability means that you know which supplier lots were used in which finished products and who received those finished products.

The system ensures each weighed ingredient has enforced - tolerances preventing recipe completion until all ingredients are weighed using the green the target zone. Lot tracking or batch tracking helps your business with product traceability to keep track of which of your customers received specific groups or shipments of items and when they were received. This information should be searchable based on transaction code serial number or lot code.

Industry-built to support your quality and safety systems SYSPROs Lot Traceability module offers a full traceability system helping you improve governance and drive compliance to minimize the effects of a recall. With a lot traceability system you have a way to track problem goods from the customer all the way back to the supplier who sent the raw materials and all the. Users can identify which materials require lot trackingand the stages of production where information needs to be recorded throughout the manufacturing process.

Putting Traceability Top of Your Business Agenda. Industry-built to support your quality and safety systems SYSPROs Lot Traceability module offers a full traceability system helping you improve governance and drive compliance to minimize the effects of a recall. This is because a modern WMS uses new technology to track the movement and storage of materials and finished goods creating real-time information about materials.

Matrix Controls provide ERP Integration Services. How ERP equips electronics manufacturers with the tools to prosper in post-Brexit Britain. Ad Intelligente Produktentwicklung mit SAP Enterprice Product Developement.

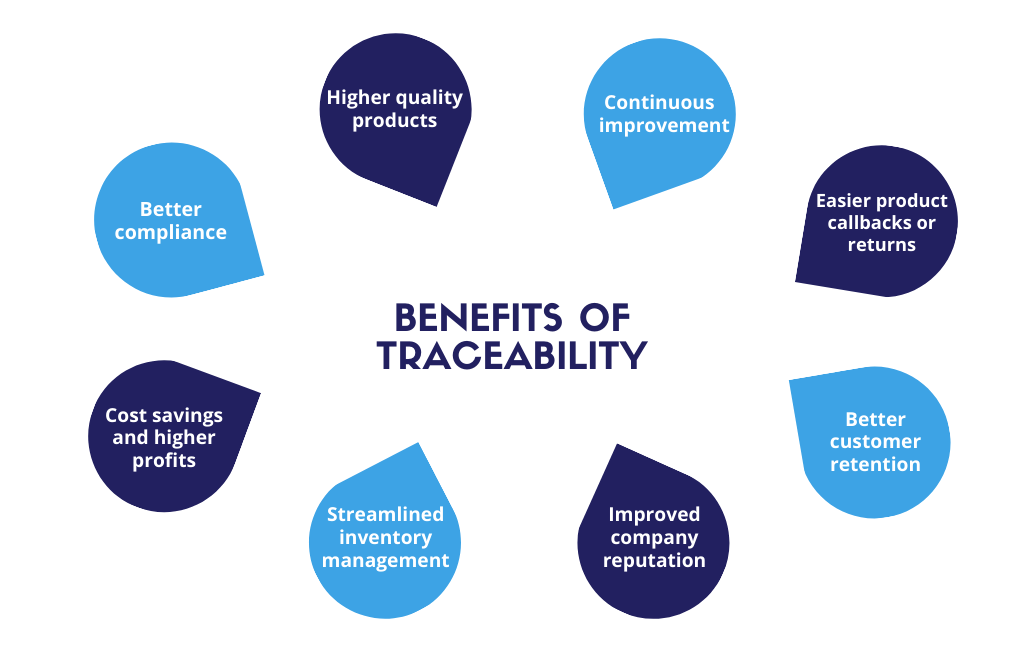

Advantages of Implementing Lot Traceability Software in Manufacturing Quality control measures are paramount to manufacturers as is the ability to monitor components as they move through the production process. Lot traceability software can be purchased as a standalone but is often contained within a modern carefully crafted ERP system. Nutzen Sie das Innovationspotential und fördern Sie die Transparenz in Ihrem Unternehmen.

Ad Intelligente Produktentwicklung mit SAP Enterprice Product Developement. The benefits of Lot Traceability Tracks the part from receipt of materials into production and through to product delivery and inventory transaction records lotserial information Track which lot controlled items were used to produce specific finished products in manufacturing process. In the video below we show you how this works using WiSys WMS for Macola.

Traceability can be challenging especially because problems can occur at any point in regulated industries. The right food processing lot traceability system can track and trace products from the farm to the point of sale. Lot traceability is the act of tracking and documenting a lot batch or group of goods that were made during the same manufacturing run using the same raw materials components and parts.

A graphical lot traceability tool executes bi-directional searches to pinpoint on hold inventory vendor deliveries and customer shipments. The systems scans and validates lot numbers providing real time inventory usage and eliminating costly traceability paperwork. 8 reasons why SYSPRO 8 is manufacturings ERP system of choice.

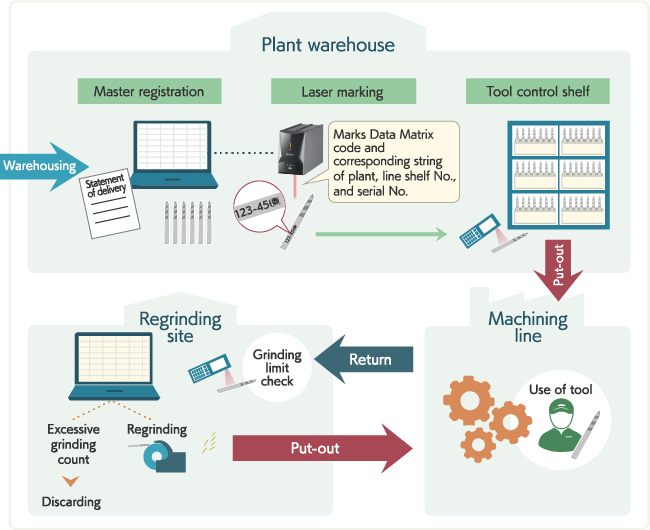

A Lot tracking system is a system that records information associated with a batch of product. A User can determine what can be purchased or sold by Lot status. Increasingly were seeing manufacturers invest in machine vision systems to keep better track of parts as they move through the assembly line.

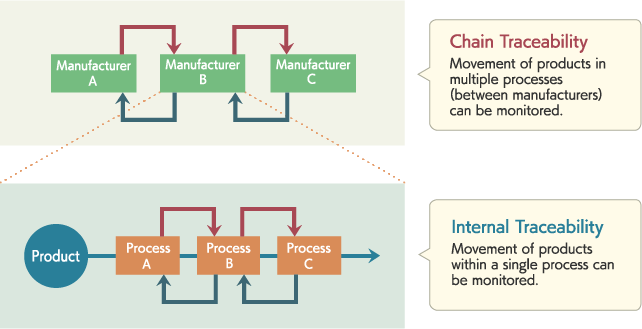

Key benefits of Lot Traceability Traceability of semi-finished or finished products from the supplier of raw materials through to the customer History of traceable-item transactions for accountability and customer service follow-up Manual or automatic lot numbering by single products or batch. It should provide search capabilities for all batch information. For traceability in manufacturing processes each product or lot is assigned an identification number and then information such as work details inspection results and dimensions are linked to this identification number in each process so that it.

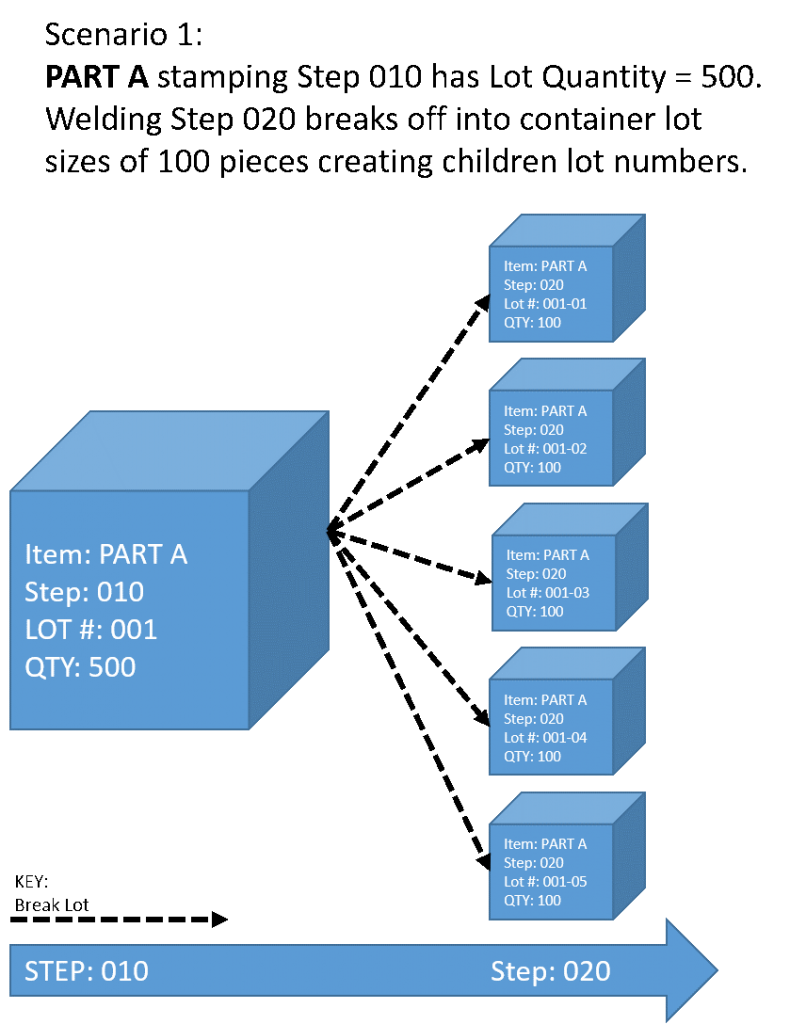

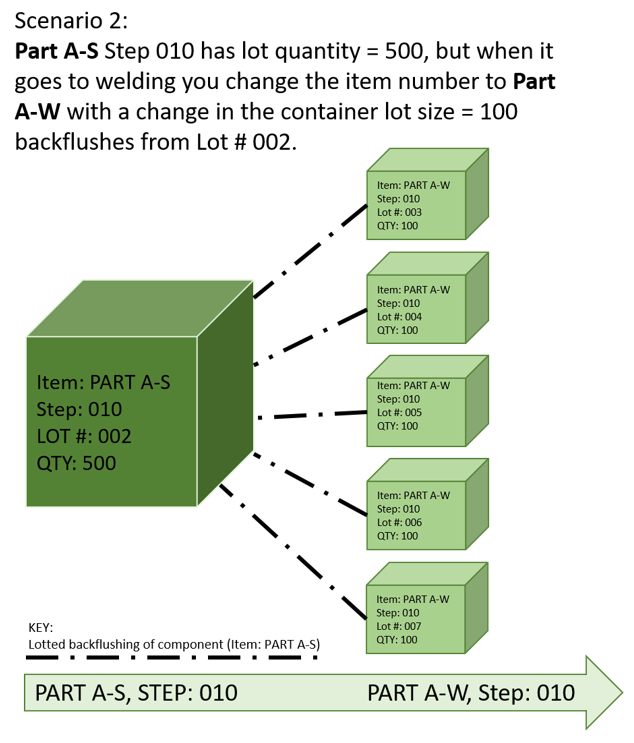

It caters for the tracking of materials through receipt manufacture assembly inspection stocking and final distribution. Lot Control Issues in Traceability Traceability is simple if the manufactured material is going to move through the production process together from front to back as a group. The technology can improve overall operations and boost customer satisfaction as the analytics used by RFID can help staff avoid running out of a product.

Data should be filtered based on customers suppliers or tasks. Implementing RFID food traceability systems in the hospitality industry will also ensure that food products such as meat fruit bread and dairy products remain within a safe temperature during storage. Nutzen Sie das Innovationspotential und fördern Sie die Transparenz in Ihrem Unternehmen.

In turn manufacturers will achieve high-level companywide traceability to ultimately reduce time valuable resources and the costs incurred by defective. Lot tracking allows you to track several units of a stock item using the same lot or batch no. It could be as simple as knowing what raw material went into a particular batch of product.

ERP helps build resilience and exploit new opportunities in mechanical equipment sector. It is when the material starts getting broken from the original lot or merged with material from other container lots that manufacturers face a challenge in quality control. It caters for the tracking of materials through receipt manufacture assembly inspection stocking and final distribution while maintaining quality.

BatchMasters lot traceability software can help food manufacturers exceed product traceability and recall code requirements stipulated in BRC SQF advanced food safety certification programs. Quality for SYSPRO by uniPoint. The lot might be the date of shipment a shift change or a change in the supply lot.

Top 5 criteria of a great Lot traceability system that blockchain can upgrade Gaining Lot Control. The supplier you purchased from and date in which the items were purchased is also recorded allowing you to track an individual group of products or shipment from your supplier.

What Is Traceability And How To Achieve It Mrpeasy

What Is Traceability Traceability Solutions Keyence America

Importance Of Lot Number Lot Number Tracking Capabilities

Structure Of A Food Traceability System Download Scientific Diagram

Traceability In The Production Process Technical Article Macsa Id

What Is Traceability Traceability Solutions Keyence America

Traceability Lot Control And Quality Assurance Aim Computer Solutions

Traceability System Product Tsukasa Industry

Traceability Lot Control And Quality Assurance Aim Computer Solutions

![]()

Lot Traceability Software For Process Manufacturing

Lot Traceability And Recall Management System

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Lot Traceability Erp Software Lot Tracking Erp System Syspro

Basics Of Lot Traceability Recall Containment Youtube

What Is Traceability Verifarma

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Product Information Traceability System

![]()

Operator Systems Track Trace Production Across The Entire Supply Chain Production Genealogy

What Is Traceability Traceability Solutions Keyence America

0 Response to "lot traceability system"

Post a Comment